The art of designing Pure Charge&Go Nx

Aaron Jacobs

Connectivity is undoubtedly one of the most important topics in the hearing aid industry today. While most people immediately associate the word connectivity with being able to link their hearing aids with electronic devices such as smartphones, in a genuinely patient-centric hearing system the application of connectivity encompasses more than simply connecting to personal electronic devices. Of at least equal importance is using connectivity to enhance the hearing aid’s audiological performance – this is often forgotten by wearers because audiological benefit tends to be less tangible than easy to understand features such as direct Bluetooth connection to the wearer’s smartphone. This article will highlight the applications of wireless technology and explore some of the technical challenges which arose during the development of the Pure Charge&Go Nx – a fully featured hearing aid which includes own-voice processing, direct streaming, and lithium-ion rechargeability.

In 2004, Signia (formerly Siemens Hearing Instruments) was the first hearing aid manufacturer to introduce a near field magnetic induction (NFMI) wireless system, which allowed hearing aids to synchronise user controls and aspects of signal processing. In 2012, the development and commercialisation of NFMI technology in hearing aids was affirmed when the three chief researchers involved in the development won the prestigious Deutscher Zukunftspreis (German Future Prize). Today, the signal processing applications relying on an NFMI link have expanded so that Signia arguably offers the most comprehensive and advanced application of NFMI technology in hearing aids. More recently, hearing aid brands (including Signia) have implemented Bluetooth in hearing aids – a radio frequency (RF) wireless system which provides connectivity with personal electronic devices such as smart phones and televisions.

The physical properties of different frequency spectra determine which wireless system is best suited to a specific hearing aid feature. An electromagnetic wave can be described either by its frequency or wavelength (according to the formula where c is the speed of light which is constant, and λ is the wavelength). The advantage of a long wavelength is that it experiences less attenuation when travelling through objects. An everyday example of how different wireless wavelengths behave can be seen with mobile phone networks. All else being equal, network providers who use a lower frequency spectrum (e.g. 900 MHz) achieve better coverage when mobile devices are used indoors. The longer wavelength (associated with the lower frequency) is more effective at travelling through building structures than shorter wavelength spectrum (e.g. 1800 MHz). Similarly, the features in a hearing aid must be matched to the inherent strengths and weaknesses of different wireless systems.

NFMI systems are best suited for scenarios where data and speech information are constantly shared while the client is wearing their hearing aids. The Signia NFMI system operates at 3.28 MHz, which is a relatively low frequency on the electromagnetic spectrum and allows so called near field magnetic induction (NFMI) communication which uses the magnetic component of an electromagnetic wave to transmit information over short distances. With extremely low power consumption, the NFMI system reliably transmits data over a range of approximately 1 metre. Binaural processing relies on the NFMI system so that the hearing aids can respond to the wearer’s environment as one system, rather than as two uncoordinated devices. This has made it possible to develop sophisticated signal processing capabilities such as real-time own-voice processing (OVP), and high performance binaural directivity (Narrow Directionality and Spatial Speech Focus) while maintaining spatial performance (HD Spatial).

Compared to NFMI systems, an RF system consumes more power. However, an advantage of RF is high bandwidth transmission over longer distances (up to 30 metres in line of sight). The wavelength of the 2.4 GHz RF signal is 12.5 centimetres, compared to about 90 metres for the 3.28 MHz NFMI signal. Because of the small wavelength, RF frequencies are highly attenuated by the wearer’s head and body and are therefore unsuitable for high performance binaural synchronisation between the hearing aids. However, hearing aid manufacturers have adopted RF using the Bluetooth Low Energy (BLE) protocol because the technology was already well established in many consumer electronic devices. The benefits of RF for the hearing aid wearer are clear: greatly enhanced convenience due to connectivity with mobile phones and televisions, and improved speech understanding by delivering the desired signal directly to both ears.

Due to the advantages and disadvantages associated with each wireless system, the obvious step was to design a hearing aid which utilised the benefits of each wireless system in one hearing aid. As we shall see, this created technical challenges for the engineers, because integrating separate wireless systems and electronic components into a tiny hearing aid was not straightforward.

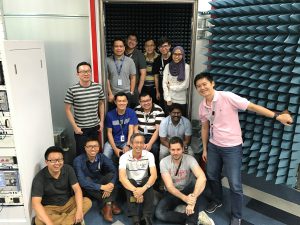

Multiple research and development (R&D) teams are involved during the development of every hearing aid. For example, there are teams who work on the mechanical design, the selection of electroacoustic components and their subsequent optimization, plus teams involved in the design, coding and testing of the software which is needed to fit the hearing aid. For Pure Charge&Go Nx, the teams involved with wireless and rechargeability themes had an especially important role. Worldwide more than forty Signia engineers work on the development and integration of wireless systems (Figure 1 shows the wireless team who were responsible for Pure Charge&Go’s Nx development).

Figure 1: Pure Charge&Go’s Nx Singapore based rechargeability and wireless team outside the wireless test chamber.

Dr. Andreas Schreiber is the Product Manager who is responsible for Pure Charge&Go Nx. An important aspect of Andreas’ job is to understand the needs and wants of hearing care professionals and hearing aid wearers, and to translate these needs and wants in to requirements which are handed over to R&D. According to Andreas: “Despite the various technologies used in Pure Charge&Go Nx, the hearing aid doesn’t break the golden rule that small size is super important. It’s for this reason that Pure Charge&Go Nx is a complex product. It’s the only product on the market which combines lithium-ion inductive charging with direct Bluetooth streaming – which means people using Apple products don’t need an intermediate streaming device which is worn around the neck or clipped to the wearer’s shirt. In addition, the competition doesn’t offer real-time own-voice processing, which we call OVP.”

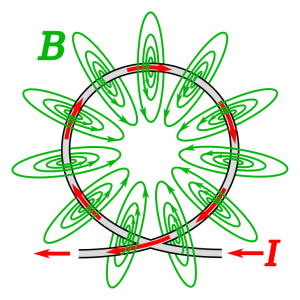

The inductive charging system in Pure Charge&Go Nx is more advanced than simply using coils to transmit and receive energy without the use of charging contacts (see Figure 2 for a short explanation on the principle of inductive charging). Inductive charging is now common in products such as premium smart phones, where probably the best known inductive charging standard is Qi. As Andreas explains, “if we use a 3.8 volt reference, which is roughly the standard voltage used by many lithium-ion batteries, mobile phones can have battery capacities of over 4000 mAh. The tiny Pure Charge&Go Nx on the other hand uses a battery with a 17 mAh capacity. Because the energy consumption of phones and other electronic devices are far higher than what’s needed by a hearing aid, we had to find a way to safeguard the hearing aid against inductive chargers designed for other devices.”

Figure 2: when an alternating current (I) is passed through a wire or coil, a magnetic field is generated (B). A receiving coil then converts the magnetic field to a current which is used to charge a battery. This is the basic principle used in inductive charging.

The solution created by the Charge&Go team was an authentication process for the inductive charging system. “The authentication process is triggered when the hearing aid detects an inductive charging field. The hearing aid basically sends a message to the charger and waits for a response which confirms that the two components are compatible. When this agreement is obtained, the charging process can start. For example, we want to prevent accidental charging if the customer inadvertently uses a non-compatible charger such as a Qi charging pad. Similarly, we want to prevent damage if Pure Charge&Go Nx is accidentally placed near a charging pad which is already charging another device, such as a mobile phone.”

The communication capability of Pure Charge&Go Nx can be summarised by referring to its three wireless systems: the NFMI system, the RF system, and an additional inductive wireless system for authentication when the wearer places their hearing aids in the charger. As Gee Heng Ler from the Pure Charge&Go Nx rechargeability and wireless team explains, the word harmonics was associated with many of the challenges created by combining three wireless systems and lithium-ion technology in a very small space.

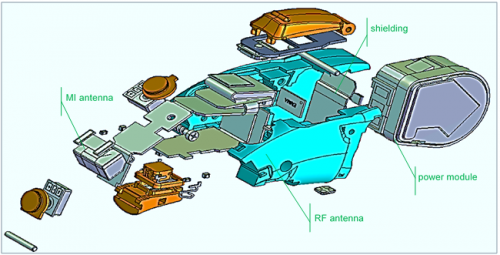

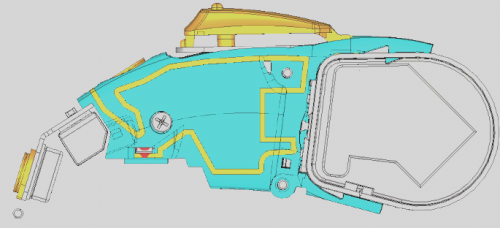

“Producing a wireless signal always generates harmonics – these harmonics have higher frequencies than the original signal and can therefore interact with wireless systems operating in other frequency bands. In a hearing aid where space is extremely limited, the potential for interference is high. Even low levels of interference can create problems in other systems. On top of managing the usual interactions between the NFMI and RF systems, with Pure Charge&Go Nx an additional major source of electromagnetic noise comes from the power module itself” (see Figure 3 and Figure 4).

Due to its chemistry, a lithium-ion cell operates at a higher voltage than standard zinc-air batteries, for which hearing aid electronics are designed. According to Ler, the power module is more than just a battery: “the lithium-ion power module operates at 3.8 volts and this is stepped down to 1.3 volts using a highly efficient voltage converter contained in the power module itself. We lose very little energy in the down conversion, but the step down creates electromagnetic noise which becomes important when two wireless systems are operating less than a couple of centimetres from the power module.” One method used by the development team to handle this challenge was to first use the simplest solution – design the hearing aid to achieve sufficient physical separation between the three sources of greatest interference: the MI antenna, the RF antenna, and the power module. As Ler explains: “doing so was a painstaking process of fine tuning, testing, more fine tuning, more testing, and so on.”

Dr. Bernd Matschkal is part of the Platform Development Team in Germany which is responsible for creating the various components in the wireless system and constructing the technological modules which are used in Signia hearing aids.

Figure 5: Chee Kong Siew, head of the Pure Charge&Go Nx rechargeability and wireless team Singapore, wears Pure Charge&Go Nx hearing aids during RF antenna performance testing in the wireless test chamber. The test chamber is shielded from even the weakest electromagnetic fields so that the very low power wireless signals used by the hearing aids can be accurately measured.

Bernd’s everyday work is highly technical and involves topics such as the air data rate, modulation schemes, multiplexing, and packet handling, which mostly sound like a foreign language to a layperson. More broadly, the Wireless Platform Team develop antenna concepts, parts of the so-called Application Specific Integrated Circuit (ASIC for short, which are purpose-built chips which deliver high processing speeds with low power consumption). In addition, the wireless architecture is developed in collaboration with other departments and external suppliers. After listening to Bernd talk for several minutes, something became clear. That is, the performance of the various modules strongly influences the quality of the final hearing aid. Bernd provides an example: “Antenna design and positioning are really important. The antennas are first computer simulated by our antenna designers in Germany or Singapore to investigate the antenna performance and identify how we can improve their function. This happens well before the hearing aid itself is actually designed.” The function of an antenna is to transmit and receive a desired signal. Generally, the bigger the antenna the better the performance, which is contrary to the design philosophy of hearing aids – and something that created a challenge for the development teams. “Ultimately, the RF antenna’s performance is tested when the actual hearing aid is worn by a real person in the wireless test chamber” (see Figure 5). An analogy is that the platform development team are responsible for creating the materials needed to construct an impressive building. The job of the product development team is to find a way to put the various modules together for the best possible result.

So, what were some of the specific techniques used to improve the wireless performance for Nx? Bernd replies: “Well, we introduced digital filtering to reduce the bit error rate and the system components are carefully matched in terms of things like clock speeds. A lot of work went in to optimizing the modulation scheme for the MI system too.” In simple terms: by improving the quality of the signal rather than the strength of the signal, the size of the MI antenna was reduced without compromising performance. The stability of the system was also markedly improved. In short, the Nx wireless system works smarter instead of harder, which is especially important for reliable operation when the final product must be tiny and must have very low power consumption.

The appeal of Pure Charge&Go Nx is that every available technology is combined to make the wearer’s ownership and listening experience as convenient and natural-sounding as possible. Advanced binaural processing delivers a natural sounding own-voice, outstanding performance in noise, and a sense of open spatialness. Pure Charge&Go Nx utilises Bluetooth so that the wearer can conveniently connect to mobile devices, which provides improved speech understanding when talking on the phone or when watching television, due to binaural streaming and separating the streamed signal from ambient noise. From a usability perspective, the wearer no longer needs to cope with tiny batteries – the lithium-ion battery with contactless charging makes daily use easier and more reliable than ever before. Most importantly, Charge&Go is competitively small – barely larger than a conventional 312-sized receiver-in-canal hearing aid. The technical challenge of designing Pure Charge&Go Nx was best summarised by Bernd during our conversation. In his words: “A change in a single component can affect everything else.”

Aaron Jacobs worked as a clinical audiologist in Australia before starting at Sivantos Pty. Ltd. (formerly Siemens Hearing Instruments) as a product trainer. In 2010, Aaron relocated to Sivantos GmbH in Germany (formerly Siemens Audiologische Technik) where he was employed as a Software Product Manager. Since 2016, Aaron has worked in the Corporate Audiology department. Aaron holds a Bachelor of Mechanical Engineering (Honours) from RMIT University and a Master of Clinical Audiology from the University of Melbourne.